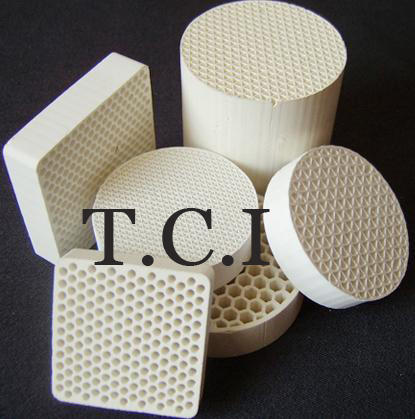

Ceramic honeycomb

1, The purification of the tail gas of automobile, eliminate noise

Automobile tail gas purification device adopt thin wall cordierite quality honeycomb ceramic carrier, The noble metal type of coating and rare-earth element, the excessive metal,etc. cover the catalyst made jointly, Automobile CO of coda, HC, NOx,etc. harmful to compositions, Burn through catalysis principle up to the discharge standard that the country stipulates.  Main technology is criticized and marked Main technology is criticized and marked

(1)Catalyst get up temperature of firing 200-230℃

(2)Use the temperature range

250-950℃

(3)The normal service life of products is 80,000 kilometers( or 2 years)

(4)Purify rate Co2.2g/km

THC+NO*0.5g/km

2, Heat exchanger, regenerative body, the sweetening of the waste gas , Take off the nitrogen

Utilize honeycomb to be ceramic heavier than the surface area , able to bear the high temperature, hold the characteristic such as being heavy of heat, Adopt special device and proper catalyst , utilize so as to remaining energy , economize cost, Protect the environment. Collect and economize energy with protect the environment and wait for multi-functional to on an organic whole( machine), adapt to on power plant extensively, The smeltery, the large-scale equipment of the incinerator .  Main technical indicator Main technical indicator

(1)Enter the temperature degree Room temperature

(2)Temperature of combustion chamber ≥1280℃

(3)Most high to use temperature 1350℃

(4)The hot coefficient of expansion 2.5*10 - 6 / ℃

(5)It is hot to shake performance( the sample) ??? 850 ℃ does not split three times

(6)≥%

Heat conduction coefficient

Heat holding

Chemical composition

SiO2 |

Al2O3 |

MgO |

Fe2O3 |

Na2O |

K2O |

48-51% |

31-34% |

14-16% |

<0.5% |

<0.5% |

<0.5% |

3, Industry's organic waste gas purification

Regard thin wall honeycomb pottery of cordierite as carriers, utilize active alumina , Noble metal coating material, make with meticulous craft whole catalyst make their have surface accumulate largly, Air current obstruction little, get up and fire low temperature is high to purify rate, Heat-resisting performance getting kind characteristic, apply petroleum, chemical industry to extensively, Smelt, the waste gas in coating,etc. is dealt with.  Main technical feature Main technical feature

(1)Purify rate ≥ 90%

(2)250 ℃ of ≥ of temperature

(3)The catalyst bears temperature 1300℃

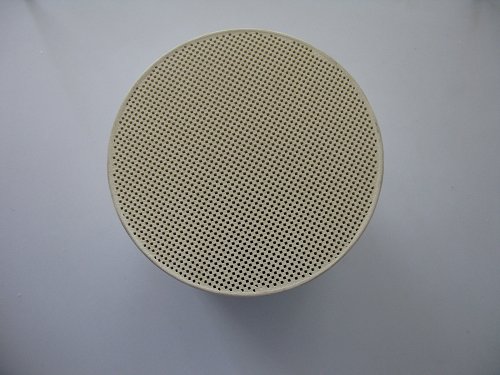

4, Honeycomb pottery filter slice

Properties of product:

Applying to metallurgy mainly, cast the trade, this product is more heavily than the surface area, Mechanical intensity high, heat-resisting characteristic that assaults , can be strained and get rid of the metal and liquid impurity in casting the products, Reduce the air vent of castings, raise the quality of casting, reduce and cast the cost, Raise labour productivity.  Main technical indicator Main technical indicator

(1)The utilization ratio increasing 5-10%

(2)Casting tired intensity increases by 15.5%

(4)Spend 1700 ℃ fire-resistantly

5, Honeycomb pottery burns the board

Utilize product this burn abundant , than surface area heavy characteristic, burn board installation in the proper position where the gas has honeycomb pottery, Can make fuel burn fully , improve kitchen temperature, so as to save time, Energy-conservation, purify the air.Main technical indicator

(1)Economize the energy 15%

(2)Improve the temperature the kitchen 200 ℃ is up to 1200 ℃

(3)Purifying the air, CO content reduces by 10 times than the ordinary kitchen after burning

6, High aluminium cordierite honeycomb pottery slice

Regard high aluminium cordierite quality as main raw materials and make a board or round honeycomb ceramic carrier, The special catalyst of coating, make it become and have special intensity and toughness, Getting ruggedized, products of heat resistance, reach and can dispel petroleum, chemical products harmful gas of production process, Strain and get rid of petroleum, chemical products liquid residue of course , thus improve product quality. Main technical indicator: carrier, The special catalyst of coating, make it become and have special intensity and toughness, Getting ruggedized, products of heat resistance, reach and can dispel petroleum, chemical products harmful gas of production process, Strain and get rid of petroleum, chemical products liquid residue of course , thus improve product quality. Main technical indicator:

(1)Purify rate ≥ 95%

(2)Catalyst tolerance temperature???? ≥300

(3)Strain except that liquid residue

|